In the competitive world of this business, the selection of chocolate pumps is not just a choice but a strategic decision that can significantly influence operational efficiency and product quality. Whether you run a quaint artisanal bakery or a sprawling confectionery, the equipment you choose to handle this substance can streamline your production processes and elevate the quality of your offerings to meet the highest standards of excellence.

Precision Flow Control: Ensuring Consistent Product Quality

When it comes to chocolate pumps, precision is paramount. One of the most critical factors to consider when evaluating equipment options is its ability to offer precise flow control. The equipment’s capacity to regulate flow rates with accuracy allows for the maintenance of consistent product quality and portion control throughout the handling. Whether you’re filling molds with ganache, enrobing confections with tempered chocolate, or delicately decorating pastries with couverture, having precise control over the flow ensures uniformity and accuracy in application. Advanced features such as variable speed drives or flow meters enable you to achieve the exact dosing needed, thereby minimizing waste, and maximizing the efficiency of your operations. By investing in equipment that provides precision flow control, you can elevate the quality and consistency of your bakery’s creations, ensuring that each product meets or exceeds your customers’ expectations.

Versatility in Application: Adapting to Diverse Dessert Needs

In the dynamic world of this business, versatility is key. Your bakery likely boasts a diverse repertoire of recipes and production processes, each with its unique requirements. Therefore, when selecting a chocolate transfer pump, it’s essential to consider its versatility in accommodating various chocolate formulations, viscosities, temperatures, and particle sizes. Whether you’re working with rich and creamy ganache, smooth and glossy tempered substance, or luxurious couverture, your equipment should be able to handle each with equal finesse. Look for equipment that offers adjustable settings or interchangeable components, allowing you to adapt seamlessly to different dessert recipes and processing requirements. Versatile equipment empowers your bakery to innovate and diversify its product offerings, catering to the evolving tastes and preferences of your discerning clientele.

Hygienic Design: Ensuring Food Safety and Compliance

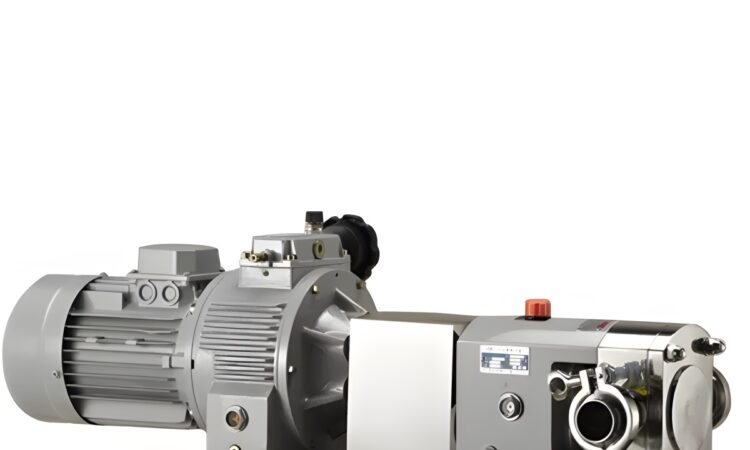

In today’s food industry landscape, maintaining impeccable standards of hygiene and food safety is not just a best practice—it’s a legal requirement. This is particularly true in the case of processing, where meticulous attention to cleanliness and sanitation is essential to prevent contamination and ensure product integrity. When evaluating handling equipment options, prioritize models that feature hygienic design elements compliant with stringent food safety standards and regulations. Seek out equipment constructed from food-grade materials that are resistant to corrosion and easy to clean and sanitize between production runs. Look for features such as smooth, polished surfaces, crevice-free construction, and removable components that facilitate thorough cleaning and disinfection, minimizing the risk of cross-contamination and safeguarding the quality of your products. By investing in equipment with a hygienic design, you not only protect the health and safety of your customers but also uphold the reputation and credibility of your bakery as a purveyor of safe and high-quality confections.

Ease of Maintenance: Minimizing Downtime and Operational Costs

In the fast-paced world of bakery operations, downtime is the enemy of productivity and profitability. That’s why ease of maintenance is a critical factor to consider when selecting devices for your business. Seek equipment with user-friendly design features and accessible components that simplify routine maintenance tasks, such as cleaning, lubrication, and part replacement. Seek out equipment equipped with self-lubricating bearings, seal-less designs, and tool-free disassembly options that reduce maintenance requirements and extend the lifespan of the equipment. Additionally, consider factors such as the availability of spare parts, technical support, and servicing options from the equipment manufacturer to ensure prompt repairs and minimize downtime in the event of unexpected failures.

In conclusion, selecting the right equipment for this dessert processing is a decision that can significantly impact the success and reputation of your bakery. By carefully considering factors such as precision flow control, versatility in application, hygienic design, and ease of maintenance, you can choose equipment that meets the unique needs and requirements of your bakery while ensuring consistent and exceptional results in processing. Whether you’re crafting artisanal treats, creating indulgent pastries, or decorating elegant desserts, the perfect equipment empowers you to unleash your creativity and delight customers with an irresistible array of creations. Invest in the ideal processing today and elevate your bakery’s production to new heights of excellence, ensuring that every treat that leaves your kitchen is nothing short of perfection.